The installation method of different types of load cells mainly depends on the shape of the sensor. Based on different installation environments, it can be divided into S type, cylindrical type, beam type, spoke type, bellows, bridge type and so on. Properly installed sensors not only match the corresponding scale, but also increase the productivity of the factory.

S type load cell is connected to both ends of the upper and lower threads and pulled out vertically or horizontally to test the tensile force. In addition, the other end is fixed on the device through threaded holes for pressing. (As used in the experimental press, directly measure the force in the pressure direction)

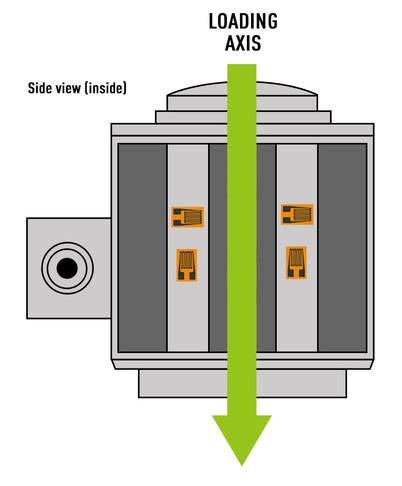

The installation method of the cylindrical load cell is to fix the bottom of the sensor on the equipment, and directly press the top to bear the force, which is generally used for large-scale force measurement occasions.

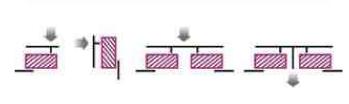

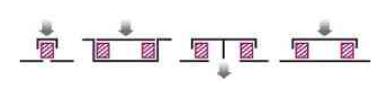

When the beam load cell is installed, the middle position needs to be suspended, one end is fixed, and the other end is stressed.

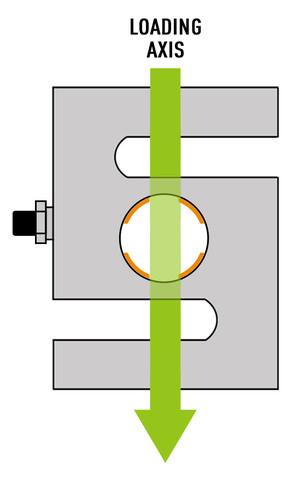

When installing the spoke load cell, the bottom of the sensor needs to be fixed on the device through 8 small threaded holes, and the pressure can be measured directly downward.

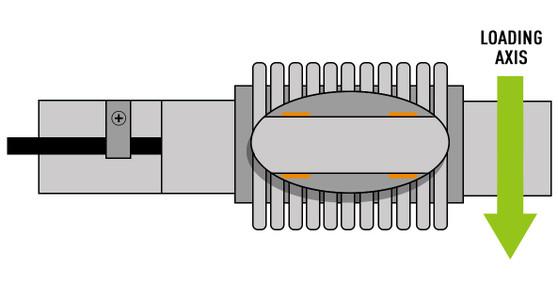

The bellows load cell is fixed on the equipment by screws at one end of the outlet, and the other end is used for force to be pressed down. (Note that when the bellows sensor is installed, the middle part needs to be suspended.) One end of the two ends is fixed for a section of force.

Bridge load cells are generally used on floor scales or truck scales. The base is directly set on the ground or on the steel plate, and the above is directly stressed through the contact surface.

No matter what type of load cell, it only needs to be completed according to the specific installation environment to achieve different work efficiency.